DPP88 liquid blister packing machine

Product DESCRIPTION

DPP88 liquid blister packing machine adopts a large transmission mechanism, and the main transmission shaft is driven by a chain, eliminating the errors and noise of other gear transmissions. The electrical appliance adopts an imported control system, and can be equipped with a missing material and missing filling device and a missing grain detection and rejection device according to customer requirements. It adopts photoelectric control system, automatic feeding of PVC, PTP, and hard aluminum packaging, and automatic punching device for scrap edges to ensure the synchronization stability of ultra-long distance multi-stations. It can be equipped with photoelectric detection and correction device, equipped with imported stepper motor traction, image and text matching printing and packaging to optimize the grade of packaging.

One complete working process is

1. Forming ( up and down heating)

2. Heating Sealing ( up heating)

3. Embossing

4. Impression

5. Cutter

6. Finished product output

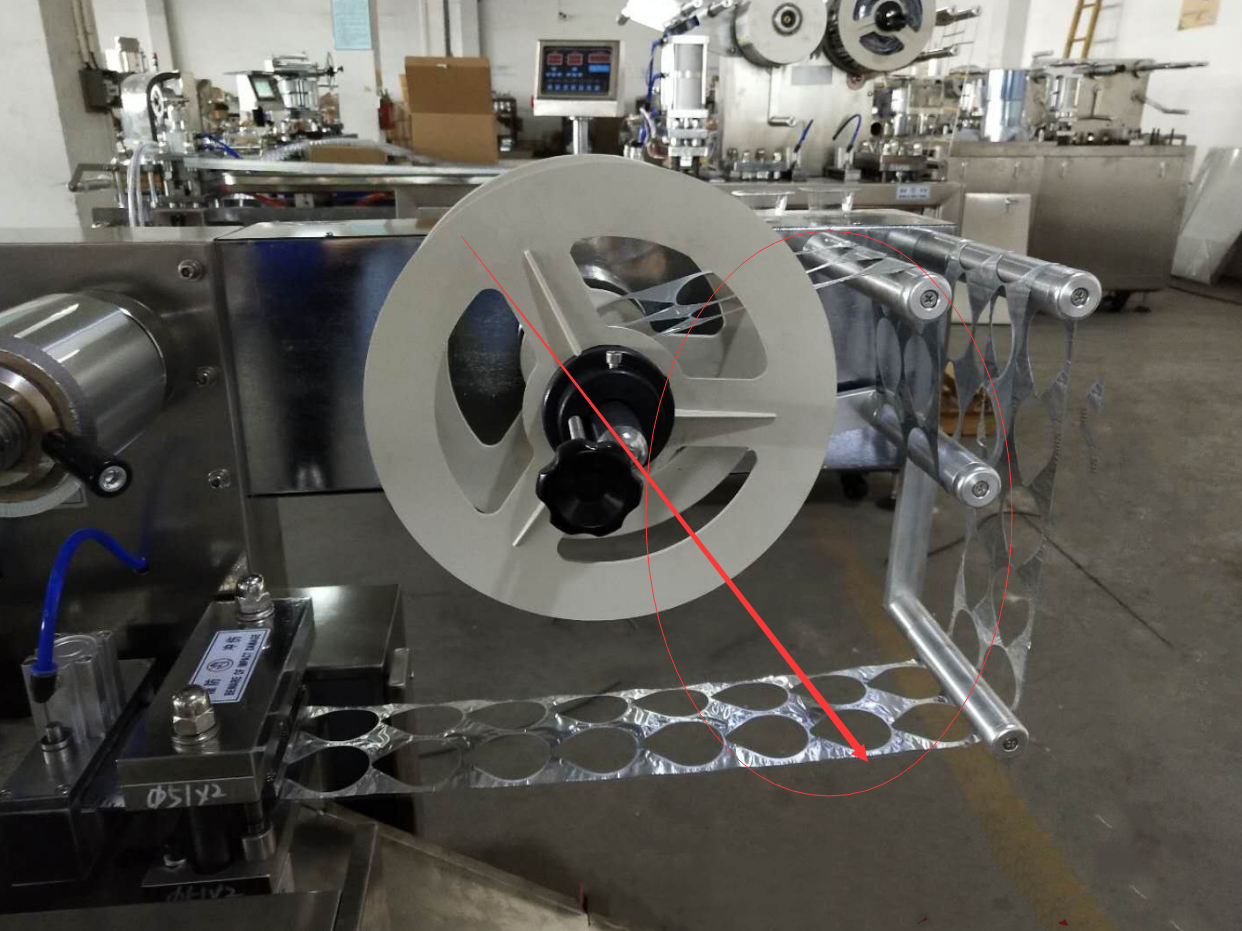

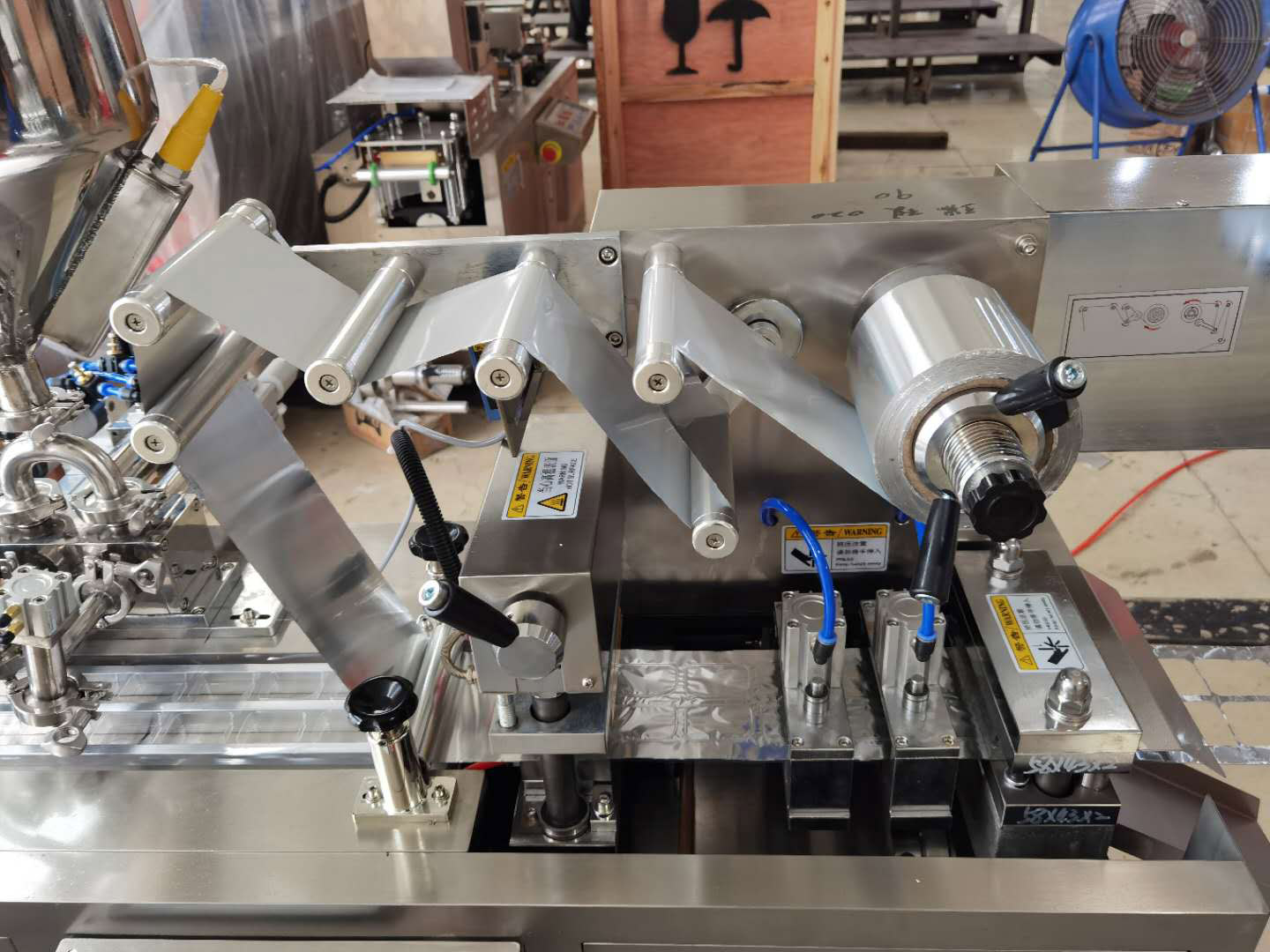

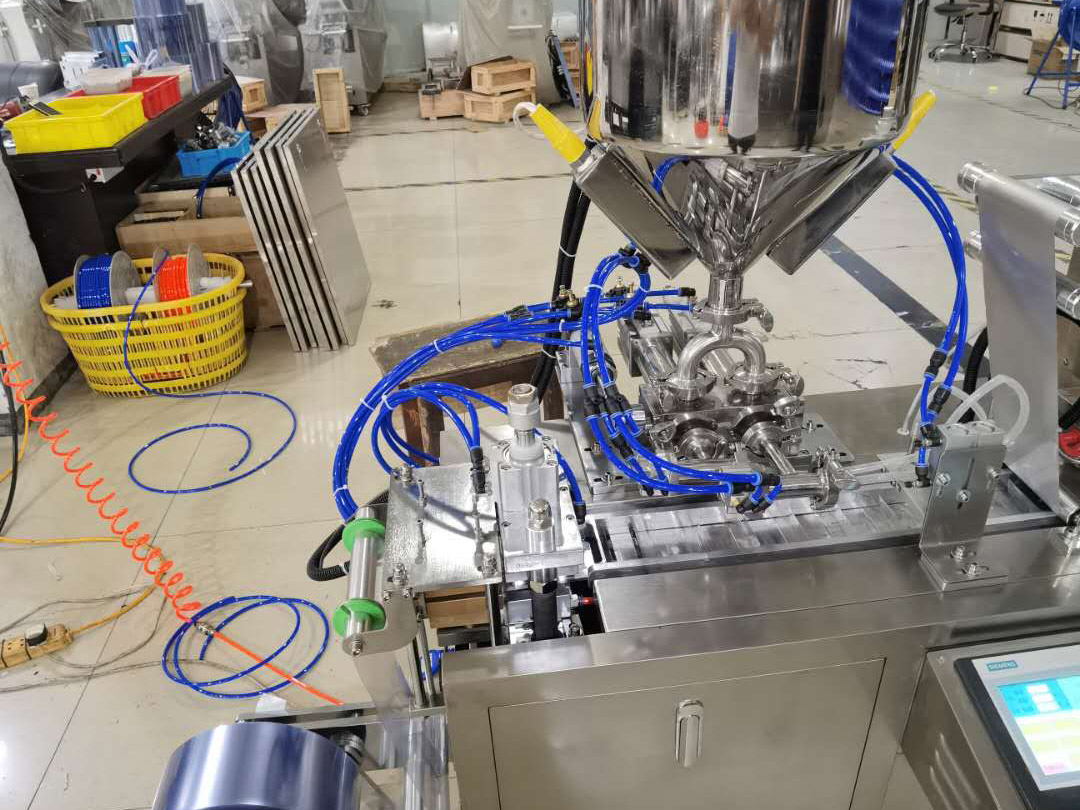

DETAIL DRAWING

Technical parameters

Model |

DPB-88 |

Punch frequency |

10-33times/min |

Production capacity |

2400plates/hour |

Max. Forming area & Depth |

105*70(standard depth ≦15mm), Max. Depth 25mm( As adjusted) |

Standard Stroke range |

30-80mm(can be designed as per user’s required) |

Standard plate size |

80*70mm (can be designed as per user’s required) |

Air pressure |

0.4-0.6Mpa |

Compressed air required |

Air compressor≥0.3m3/min |

Total power supply |

380V/220V 50Hz 2.8Kw |

Main motor |

0.75Kw |

PVC hard Film |

0.15-0.5*110 (mm) |

PTP Aluminum film |

0.02-0.035*110 (mm) |

Dialysis Paper |

50-100g*110(mm) |

Mould cooling |

Tap water or Recycling water |

Overall Dimension |

1840*590*1100 mm (L*W*H) |

Weight |

Net 450kg Gross weight: 520kg |

Noise index |

<75dBA |